Production process and quality control of shower curtain rod in China

In the Chinese bathroom hardware industry, the shower curtain rod is an indispensable accessory for bathrooms, and its production process and quality control directly affect the durability, aesthetics, and user experience of the product. Especially in Yiwu, Zhejiang, China, a globally renowned small commodity distribution center, enterprises such as Jieshang Daily Necessities Factory have demonstrated excellent skills and strict quality management in the production of shower curtain rods.

1、 Production process of shower curtain rod

The production of shower curtain rods begins with carefully selected raw materials. Jieshang Daily Necessities Factory usually uses high-quality metal materials such as stainless steel, copper, or aluminum alloy, which not only have excellent corrosion resistance and strength, but also meet diverse design needs.

1. Material preparation and processing: After selecting the material, preliminary processing such as cutting, bending, and stamping is carried out to form the basic shape of the shower curtain rod. This process requires precise mechanical equipment and skilled operating techniques to ensure the accuracy and consistency of each component.

2. Surface treatment: Surface treatment is a key step in improving the quality of shower curtain rods. Jieshang Daily Necessities Factory adopts advanced pickling, polishing, and electroplating processes. Acid washing removes surface oxides and impurities, polishing makes the surface smooth and shiny, while electroplating further enhances corrosion resistance and aesthetics, such as the common chrome plating treatment.

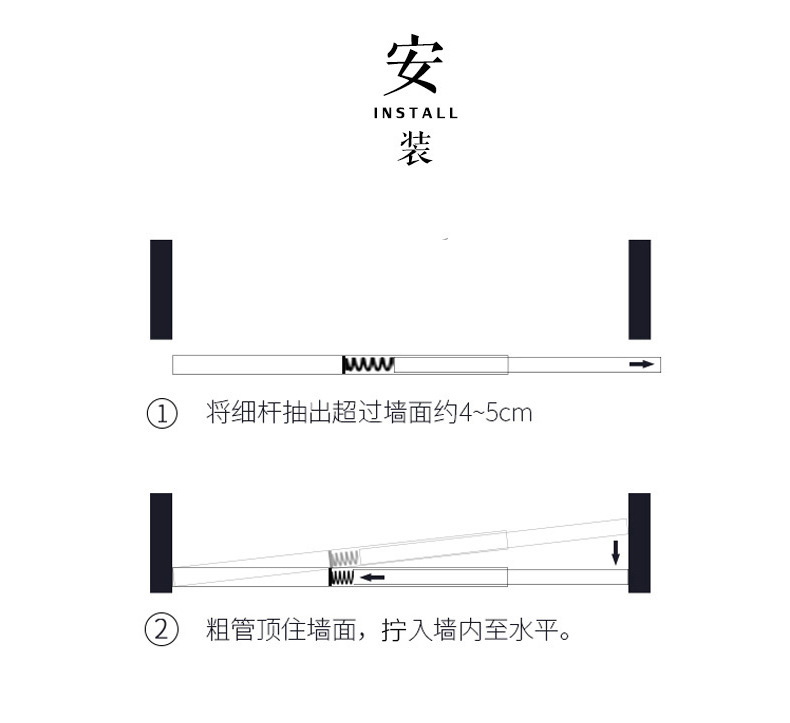

3. Assembly and debugging: After surface treatment, each component is finely assembled according to the design drawings, including welding, riveting, and other processes. During the assembly process, quality inspectors will conduct multiple adjustments to ensure that the product is installed securely and used flexibly.

2、 Quality Control System

Jieshang Daily Necessities Factory is well aware that quality is the foundation of enterprise survival, so it has established a strict quality control system in the production process of shower curtain rods.

1. Raw material inspection: All incoming raw materials must undergo strict quality testing to ensure compliance with national standards and design requirements.

2. Process monitoring: During the production process, implement full process quality monitoring to ensure that each production link meets the process standards. Quality inspectors will regularly inspect products and promptly handle non-conforming products.

3. Finished product testing: After the finished product is completed, it needs to go through multiple testing procedures such as appearance inspection, size measurement, and functional testing. Visual inspection ensures that the product surface is smooth and flawless, dimensional measurement ensures that the product meets design requirements, and functional testing verifies the product's performance.

3、 Advantages and Practices of Jieshang Daily Necessities Factory

Jieshang Daily Necessities Factory, located in Zone 4 of Yiwu International Trade City, China, has established a good reputation in the field of shower curtain rod production with its advanced production equipment and strict quality control system. The factory not only focuses on improving product quality, but also constantly innovates designs to meet the diverse needs of the market.

Jieshang Daily Necessities Factory has years of production experience and technical accumulation, and can provide customized production services to customers. Whether it is a straight shower curtain rod, a rotating shower curtain rod, or a telescopic shower curtain rod, they can all be designed and produced according to customer needs.

In addition, the factory also focuses on environmental protection and sustainable development, using environmentally friendly materials and green production processes, and is committed to reducing its impact on the environment. In the packaging process, environmentally friendly materials are used for packaging and packaging to ensure that the product is not damaged during transportation and to reduce environmental pollution.

In summary, the production process and quality control of shower curtain rods in China is a systematic project that requires enterprises to strictly control multiple aspects from raw material selection, processing and manufacturing to finished product testing. Jieshang Daily Necessities Factory, as a leader in the industry, has set a benchmark for the industry with its exquisite craftsmanship and strict quality management.